Understanding 3D Printers and Their Practical Applications

Three-dimensional printing technology has evolved from industrial machinery into accessible tools for creators, hobbyists, and professionals. These devices build physical objects layer by layer from digital designs, opening possibilities that range from rapid prototyping to personalized manufacturing. Whether you're considering your first printer or exploring new applications, understanding how this technology works and what it can accomplish helps you make informed decisions about integrating it into your projects or daily life.

3D printing represents a significant shift in how we approach manufacturing and creation. Unlike traditional subtractive methods that carve away material, additive manufacturing builds objects from the ground up, depositing material precisely where needed. This fundamental difference allows for complex geometries, reduced waste, and customization that would be difficult or impossible with conventional techniques.

The technology has become increasingly accessible over the past decade, with machines now available at various price points and capability levels. From desktop models that fit on a workbench to larger industrial systems, the range of options reflects the diverse needs of users across multiple fields. Understanding the core principles and practical considerations helps anyone interested in this technology make choices aligned with their specific requirements.

What Are 3D Printers and How Do They Function?

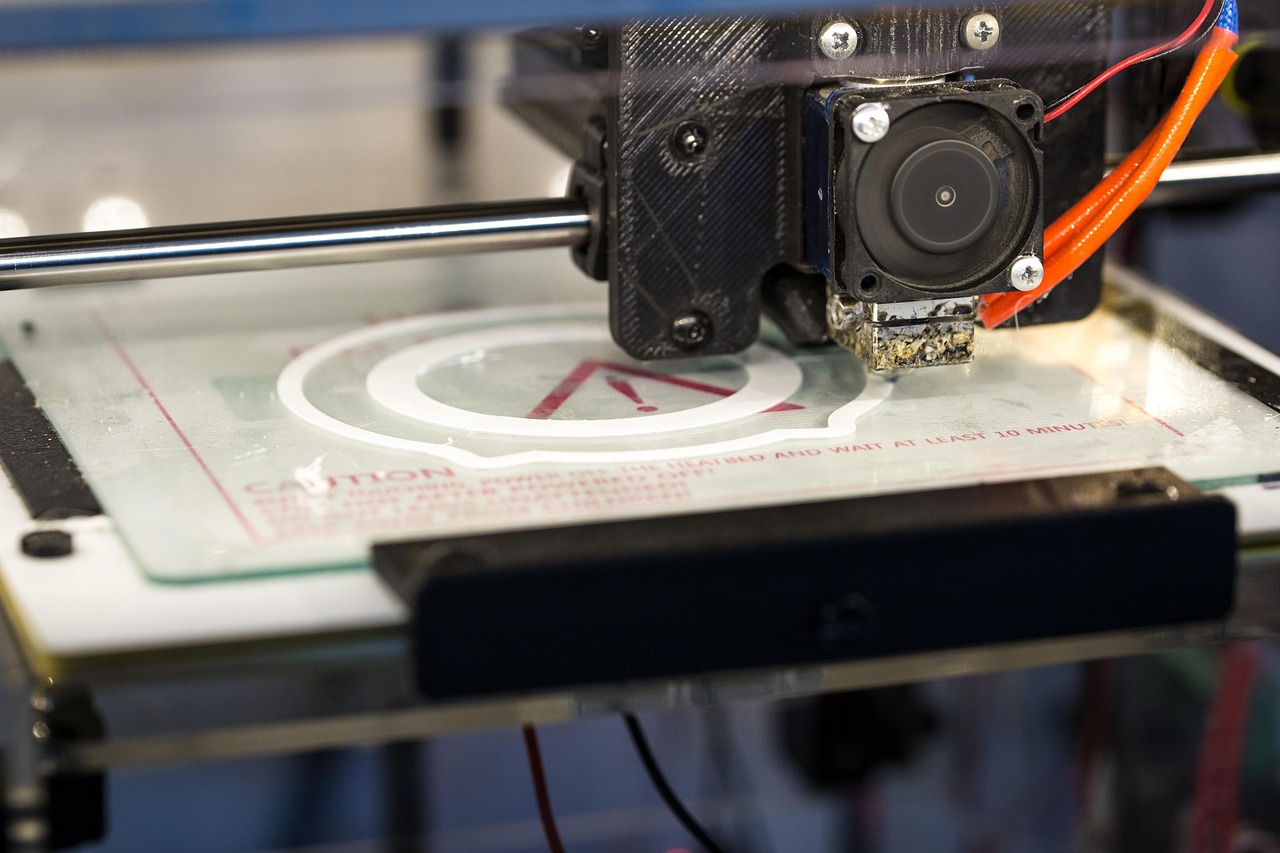

At their core, 3D printers translate digital three-dimensional models into physical objects through a layer-by-layer construction process. The most common technology for consumer devices is Fused Deposition Modeling (FDM), which melts thermoplastic filament and deposits it through a heated nozzle. As each layer cools and solidifies, the nozzle moves upward to begin the next layer, gradually building the complete object.

Other technologies include Stereolithography (SLA), which uses ultraviolet light to cure liquid resin into solid layers, and Selective Laser Sintering (SLS), which fuses powder particles with a laser. Each method offers distinct advantages in terms of material properties, surface finish, resolution, and speed. FDM remains popular for general use due to its affordability and straightforward operation, while resin-based systems appeal to users requiring higher detail and smoother surfaces.

The printing process begins with a digital model, typically created in Computer-Aided Design (CAD) software or downloaded from online repositories. Slicing software then converts this model into instructions the printer can execute, determining layer height, print speed, support structures, and infill density. These parameters significantly affect print quality, strength, and duration.

Home Use for 3D Printers: Practical Household Applications

Residential adoption of 3D printing has grown as machines become more reliable and user-friendly. Households use these devices for functional repairs, creating replacement parts for appliances, furniture, and toys that would otherwise require expensive replacements or be difficult to source. Custom organizers, hooks, brackets, and storage solutions tailored to specific spaces represent common practical applications.

Educational value also drives home adoption. Families with children find that designing and printing objects teaches spatial reasoning, problem-solving, and basic engineering principles in an engaging, hands-on manner. Students can visualize mathematical concepts, create science project components, or develop prototypes for invention competitions.

Hobbyists and makers use home printers for various creative pursuits, from miniature figures for tabletop gaming to custom enclosures for electronics projects. The ability to iterate designs quickly without relying on external manufacturing services accelerates learning and experimentation. Personalized gifts, decorative items, and artistic sculptures demonstrate the creative flexibility these machines offer beyond purely functional applications.

Ideas for 3D Printers: Expanding Creative Possibilities

The versatility of 3D printing extends across numerous domains. In product development, designers create functional prototypes to test ergonomics, fit, and mechanical operation before committing to expensive tooling. This rapid prototyping capability significantly reduces development cycles and allows for more experimental approaches to design challenges.

Small-scale manufacturing represents another significant application. Entrepreneurs produce limited runs of specialized products without the overhead of traditional manufacturing infrastructure. Custom jewelry, specialized tools, niche accessories, and replacement parts for discontinued products all benefit from on-demand production capabilities.

Educational institutions integrate 3D printing into curricula across disciplines. Architecture students create physical models of their designs, biology classes print anatomical structures for study, and engineering programs use the technology for hands-on learning about manufacturing processes. The interdisciplinary nature of the technology makes it valuable across science, technology, engineering, arts, and mathematics education.

Medical applications continue expanding, with professionals using printers to create anatomical models for surgical planning, custom prosthetics, and dental appliances. While specialized medical-grade systems differ from consumer devices, the underlying principles remain consistent, and the technology continues advancing toward more sophisticated biomedical applications.

Cost Considerations and Equipment Options

When evaluating 3D printing equipment, understanding the range of available options helps align capabilities with budget and intended use. Entry-level FDM printers suitable for beginners typically start around two hundred to four hundred dollars, offering basic functionality with manual calibration requirements. Mid-range models between four hundred and one thousand dollars generally provide better build quality, larger print volumes, and features like automatic bed leveling that simplify operation.

Professional-grade desktop systems range from one thousand to several thousand dollars, delivering enhanced precision, reliability, and material compatibility. Resin-based SLA printers occupy a similar price spectrum, with entry models starting around three hundred dollars and professional systems reaching several thousand. Industrial machines used in commercial settings can cost tens of thousands of dollars or more, reflecting their advanced capabilities and production-oriented features.

Operating costs include materials, with FDM filament typically priced between fifteen and fifty dollars per kilogram depending on material type and quality. Resin costs range from thirty to one hundred dollars per liter. Electricity consumption remains relatively modest for home use, generally comparable to running a desktop computer. Replacement parts like nozzles, build surfaces, and occasional component upgrades should factor into long-term budgeting.

| Printer Type | Price Range | Typical Use Case | Material Cost |

|---|---|---|---|

| Entry FDM | $200-$400 | Beginners, education, basic prototyping | $15-$25/kg filament |

| Mid-Range FDM | $400-$1,000 | Hobbyists, small business, reliable home use | $20-$40/kg filament |

| Professional FDM | $1,000-$5,000 | Engineering, production, advanced materials | $30-$50/kg filament |

| Entry SLA/Resin | $300-$800 | High-detail models, jewelry, miniatures | $30-$60/liter resin |

| Professional SLA | $800-$5,000 | Dental, jewelry casting, precision parts | $50-$100/liter resin |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Selecting Equipment Based on Your Needs

Choosing appropriate equipment requires evaluating several factors beyond initial cost. Build volume determines the maximum size of objects you can create in a single print, with common dimensions ranging from small cubes of about 120mm to larger volumes exceeding 300mm in each dimension. Consider both immediate needs and potential future projects when assessing size requirements.

Layer resolution affects surface quality and detail level, measured in microns. FDM printers typically achieve layer heights between 50 and 300 microns, while resin systems can reach 25 microns or finer. Higher resolution increases print time but produces smoother surfaces requiring less post-processing. The trade-off between speed and quality depends on application priorities.

Material compatibility varies significantly between models. Basic FDM printers handle standard thermoplastics like PLA and PETG, while advanced systems accommodate engineering materials such as nylon, polycarbonate, and flexible filaments. Resin printers offer materials optimized for different properties, including standard resins, tough formulations, flexible options, and castable varieties for jewelry making.

Reliability and ease of use matter considerably, especially for beginners. Features like automatic bed leveling, filament runout detection, power recovery, and intuitive interfaces reduce frustration and failed prints. Community support, available documentation, and manufacturer responsiveness to issues should factor into purchasing decisions, as troubleshooting assistance proves valuable when learning the technology.

Getting Started with 3D Printing

Beginning your 3D printing journey involves both equipment setup and skill development. Most modern printers arrive partially assembled with detailed instructions for completion. Initial calibration ensures the print bed sits level relative to the nozzle, critical for proper first-layer adhesion. Many contemporary models automate this process, though understanding manual calibration principles helps troubleshoot issues.

Learning to use slicing software represents an essential skill. These programs offer numerous settings that affect print outcomes, but starting with manufacturer-recommended profiles provides a solid foundation. As experience grows, adjusting parameters like print speed, temperature, retraction settings, and support generation allows optimization for specific models and materials.

Online communities provide invaluable resources for learning and troubleshooting. Forums, social media groups, and video platforms host extensive discussions about techniques, solutions to common problems, and project inspiration. Model repositories offer thousands of free designs to print while developing skills before attempting original creations. Many users find that a combination of printing existing designs and gradually learning CAD software provides a balanced approach to skill development.

Maintenance requirements remain relatively modest but important for consistent results. Regular cleaning of the print bed, occasional nozzle replacement, and lubrication of moving parts keep machines operating smoothly. Proper filament storage in dry conditions prevents moisture absorption that can cause print quality issues. Developing good maintenance habits early extends equipment lifespan and reduces frustrating failures.

Three-dimensional printing technology continues evolving, with improvements in speed, material options, and ease of use expanding what individuals and small organizations can accomplish. Whether applied to practical problem-solving, creative expression, educational exploration, or small-scale production, these machines offer capabilities that were once exclusive to industrial settings. Understanding the fundamentals, evaluating options carefully, and committing to gradual skill development enables anyone to harness this transformative technology effectively.